ALL SET FOR FUTURE-PROOFING PRODUCTION OF YOUR ROLLS

KOCH INDUSTRIEANLAGEN GMBH WILL BE TELLING THE CONVERTING INDUSTRY ALL ABOUT ITS INNOVATIVE DEVELOPMENTS AT THE ICE EUROPE 2019.

Using its automation expertise, KOCH Industrieanlagen GmbH successfully implements robot systems at home and abroad and has already made major contributions to the fortunes of numerous customers in many different industrial sectors – in particular in the converting industry.

The main thrust of KOCH’s engineering is on fully automatic unloading and on automated packaging and palletising using robots. Robot-aided support activities are also routinely carried out, such as positioning tubes, and labelling and weighing goods, with the systems involved linked to various databases.

The most important consideration for KOCH is always the individual requirements and products of their customers. They form the basis for the bespoke system designs – whether as integrable single systems or complete turnkey systems.

OPTIMISE YOUR PRODUCTION PROCESSES WITH DRIVERLESS TRANSPORT SYSTEMS

KOCH uses autonomously controlled, driverless transport systems to take the required primary materials but also produced rolls to the next step in the process – and it’s all without any track guiding or navigational elements. Your robots and machines are automatically supplied with new material whenever needed and this, of course, means you can reduce your reaction times and at the same time increase the flexibility of your production processes.

PACK YOUR ROLLS SECURELY FOR DOWNSTREAM OPERATIONS

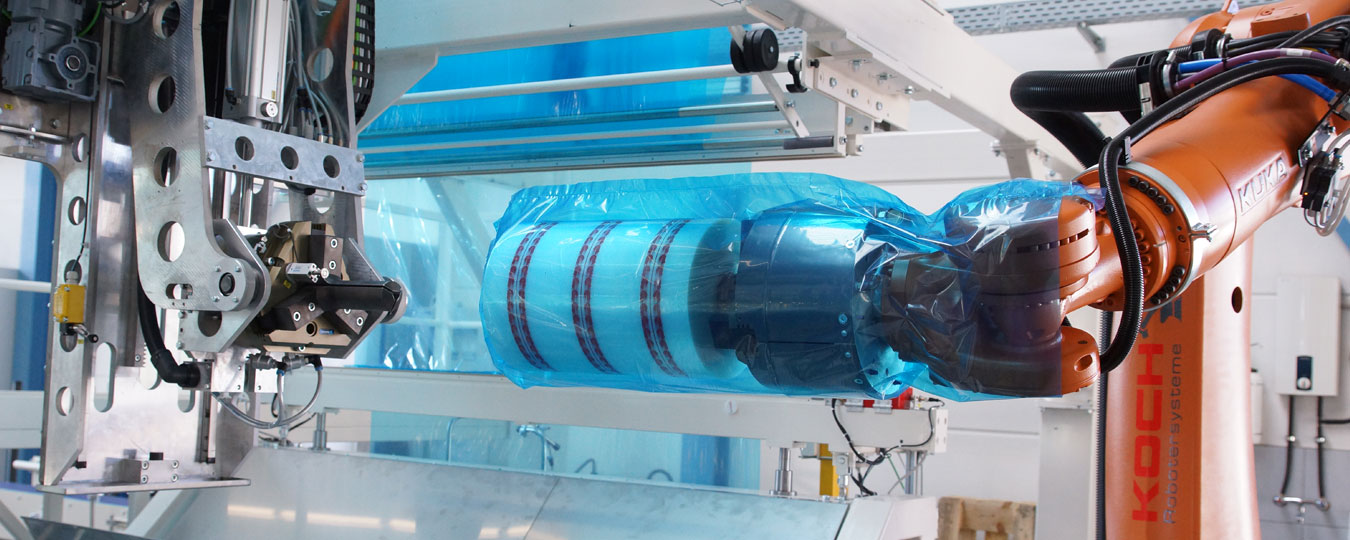

The RobotFlexPacker designed and patented by KOCH can wrap widely differing dimensions of rolls in film fully automatically. The robot-aided film wrapping machine picks up individual rolls from the feeder conveyor and takes them through a film curtain. The open sides are successively sealed and the film wrapped around the roll. The result is a close-fitting, sealed film ready to move on to the next robot process. Depending on the customer’s requirements, the roll is then transferred to the downstream conveyor system or directly palletised by the robot.

What’s more, the RobotFlexPacker boasts a wide range of applications and can be easily adapted to suit the particular needs. The machine can handle all sorts of roll dimensions one after the other and also adjust settings, such as cutting widths and sealing parameters, fully automatically. This enables production to be geared specifically to the actual conditions on the ground in no time at all.

PALLETISE YOUR ROLLS SECURELY AND WITH MINIMUM SPACE REQUIREMENTS

Thanks to the intuitive palletising software EasyReelLoader developed by KOCH Industrieanlagen GmbH, you’ll be able to match your roll palletising to your precise needs. You determine the optimum number and arrangement of your rolls at your PC and then send this layer configuration for palletising straight to your KOCH robot system.

Would you also like to optimise your production processes?

You’re looking for a competent partner with many years of experience in developing robot systems?

Then come along to the ICE europe – Hall A6, Stand 530 – in Munich from 12 to 14 March 2019 to find out how we at KOCH Industrieanlagen GmbH can help you and to discuss your system plans with us.

The KOCH team are looking forward to seeing you.