EXAMPLES OF REALISED ROBOT SYSTEMS

Below is a cross section of the more than 300 systems, we have designed and installed for both large international corporations as well as medium sized companies from different industries.

Systems

Factory areas

Your products

Centralised palletising of coffee specialties

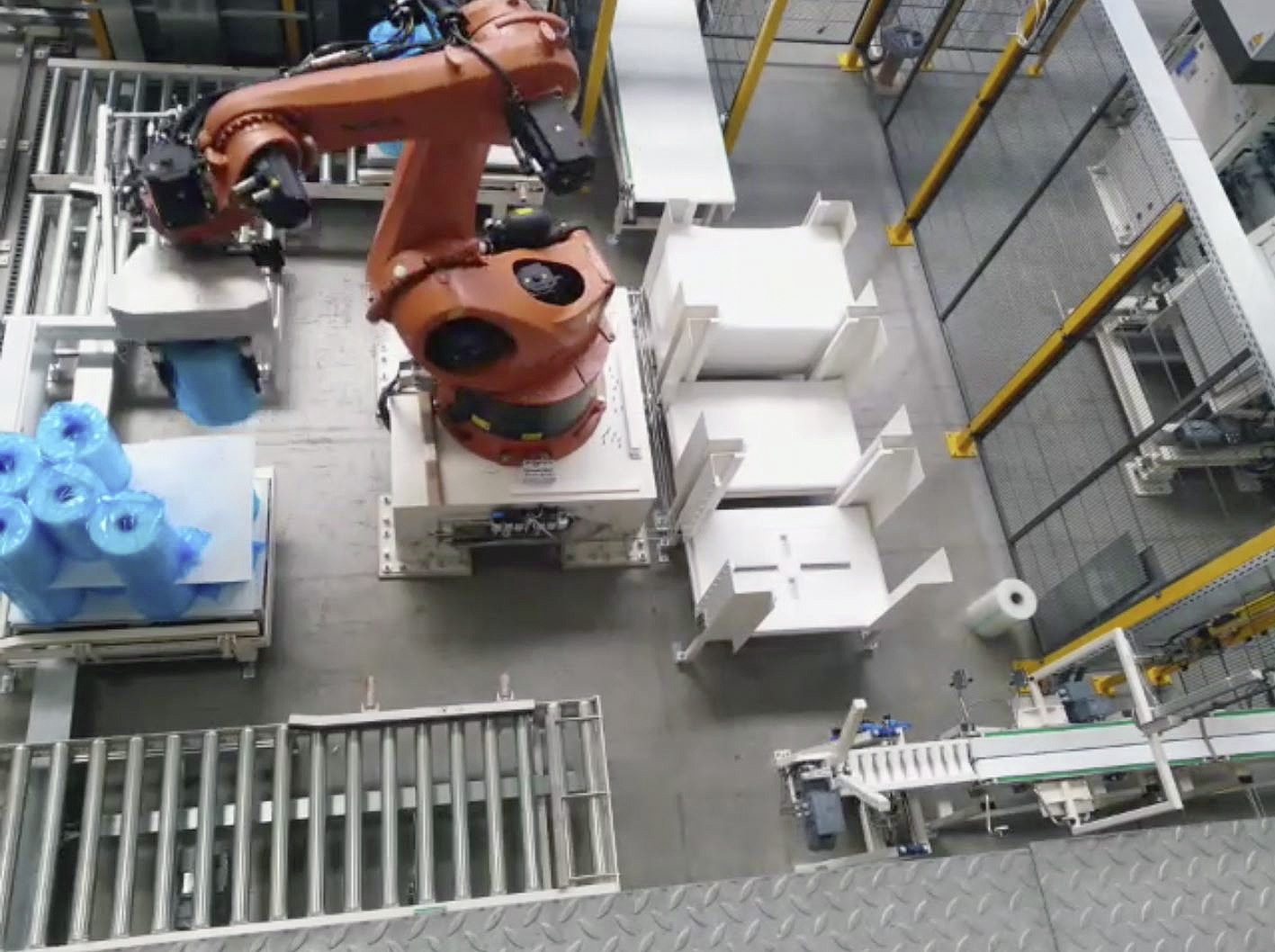

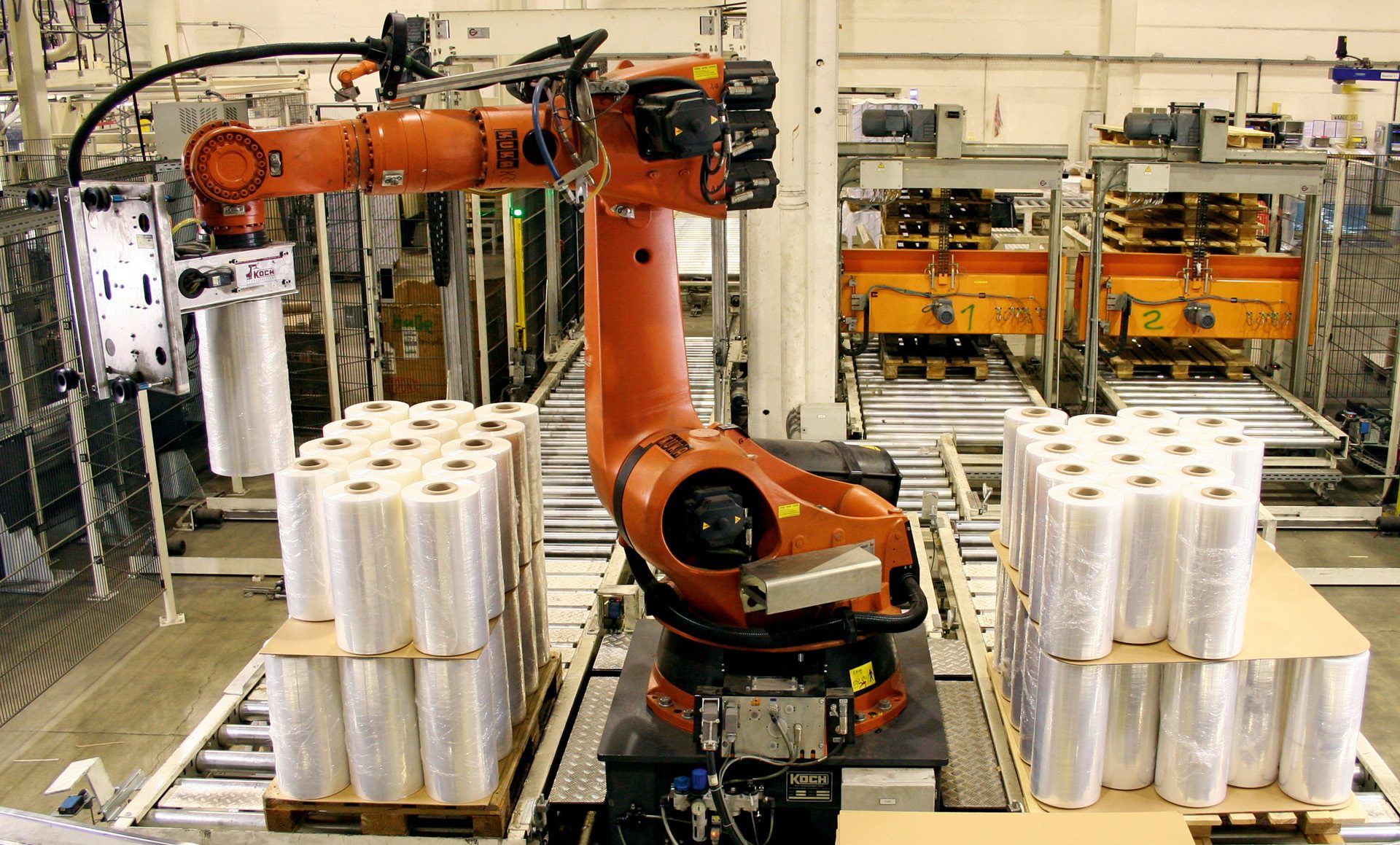

Fully automatic packaging and palletising line for rolls

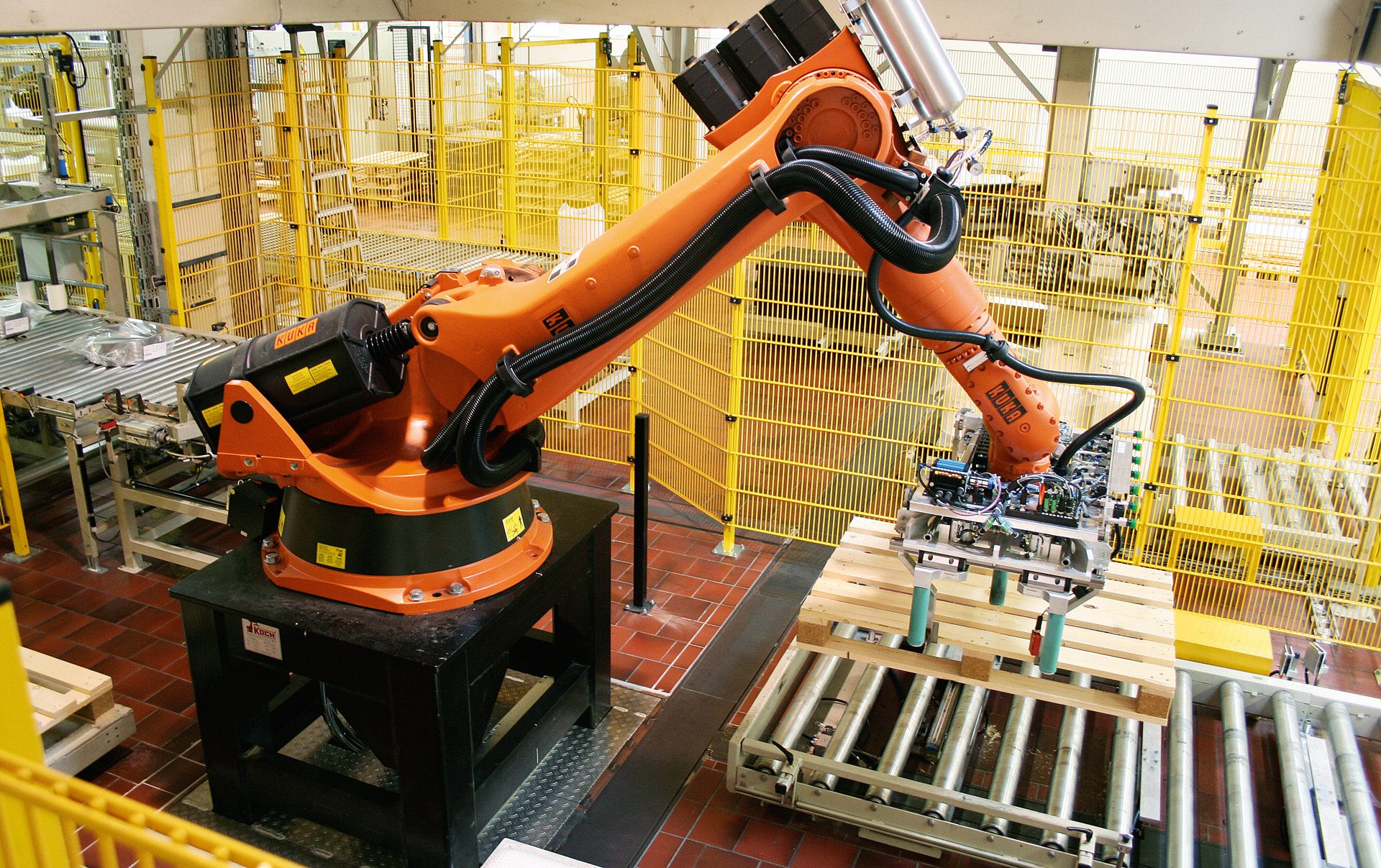

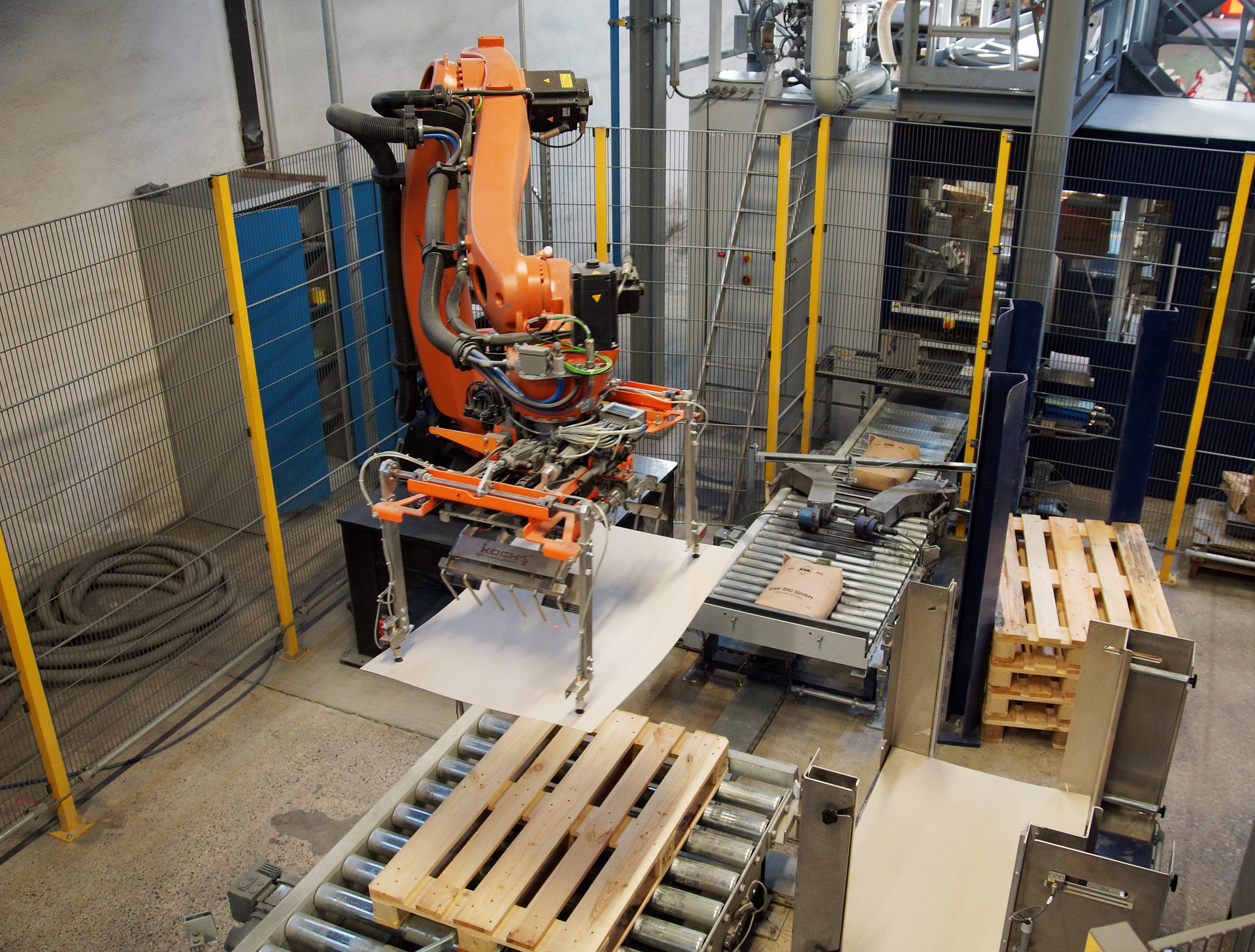

Robot palletising with KOCH special gripper for product, pallet and intermediate layer

protective layer portal; pallet safety and pallet labeller; different pallet formats

KOCH Clamping Jaw Gripper with under-grip function; protective layer and intermediate layer portal

Flexible palletising of buckets with automatic gripper adjustment for parallel and sorted processing of three production lines

Pre-grouping and automatic gripper adjustment

Depalletising individual bags with a suction gripper

Palletising two parallel production lines

Universal solutions: for boxes, trays, crates and other such containers with up to 100kg in weight, 100 – 600 mm in length and 80 – 500 mm in width

Setting up boxes, placing bags inside and closing boxes

Automatic empty pallet magazine and protective sheet gantry for auto

High packaging speeds thanks to multiple gripping

Interface to higher-level process control system with marking bags and

Labelling: placing bar code labels to within a millimetre on the tying straps of coils

Palletising both unpacked rolls and rolls packed in boxes at several palletising stations

KOCH complete system control with product tracking as well as the interfaces required

Compact standard robot palletising cells linked to four packaging lines

Palletising robot with combination gripper (for drums, pallets and top boards)

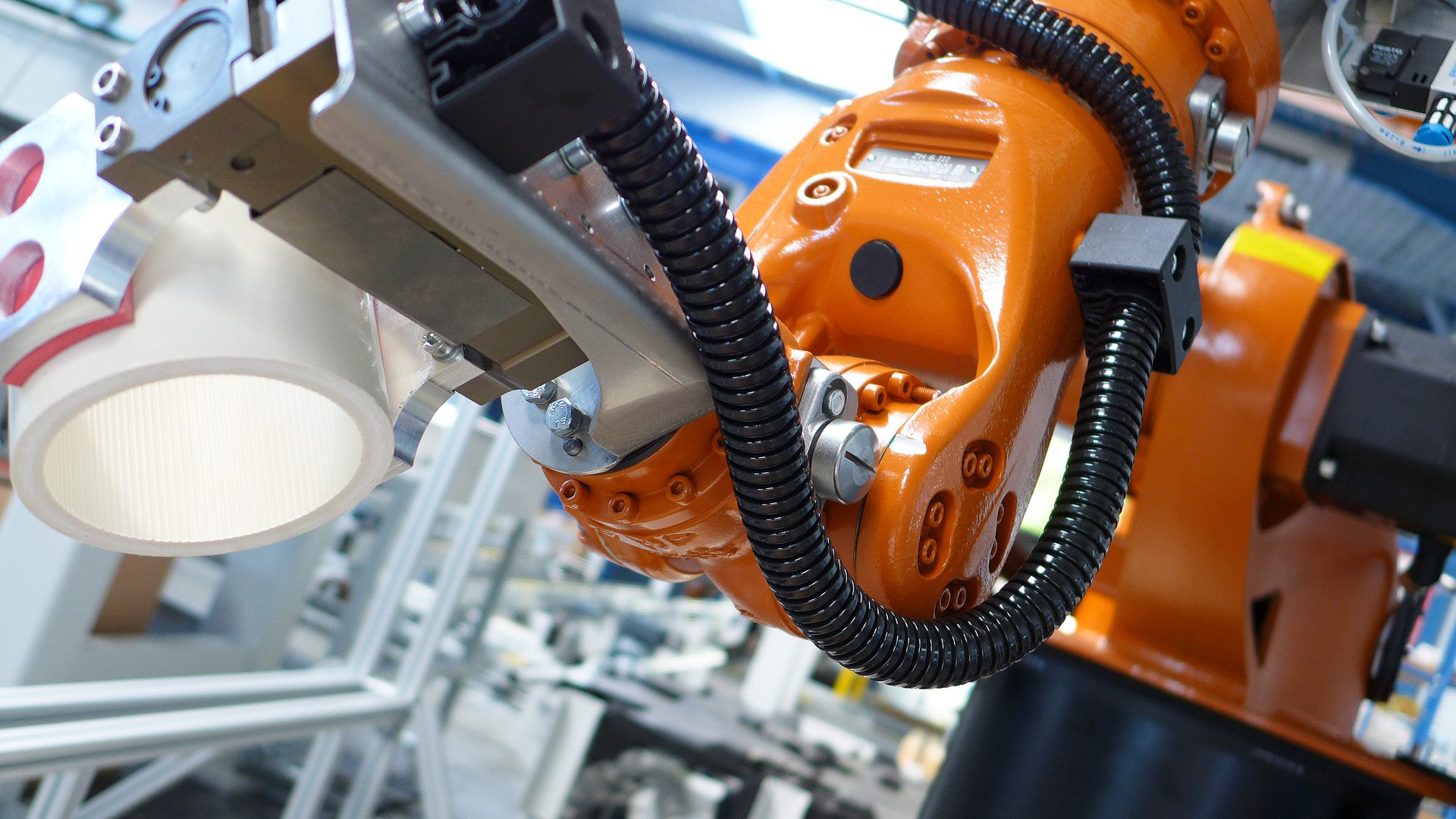

Palletising line for reels with outside clamping gripper

- Robot system with KOCH multifunctional gripper

- Outer clamping

- Product handling

- protective layer or intermediate layer portal

- Pallet handling

- Palletising of unpacked or packed reels with different dimensions without retooling

- Handling of industrial pallets, Euro pallets and special pallets

Portal for big reels and inkjet marking system

- Special solution as intermediate warehouse for big reels up to 1.200 kg

- Three-axis portal

- A total of 60 spaces

- Fully automated reel supply with FTS

- The subsequent labelling by a robot with automatic contour detection

- Processing of complete cuttings and big reels

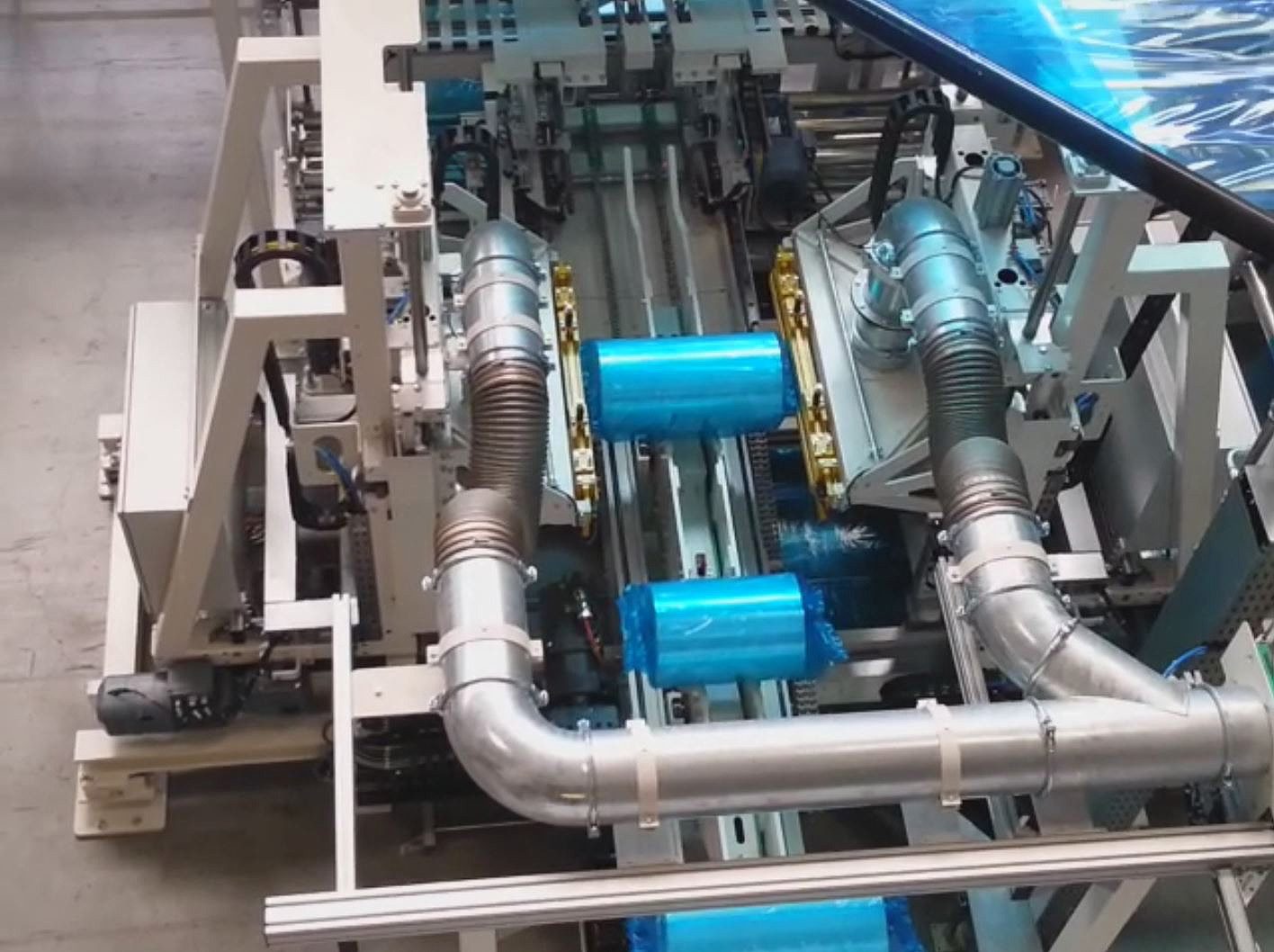

Packaging and Palletising System for reels

- Connection of two reel splitters with automated product transport and product tracking via barcode label

- KOCH palletising system with special reel gripper up to 200 kg single reel weight

- Protective layer and intermediate layer portal

- fully automated adjustable packaging system

- all batch sizes and product diversity

- sorted palletising of the incoming reels

- Automated full- and empty-pallet transport

Automated Core Positioning

- KOCH positioning robot with core gripper

- Automatic provision of empty cores for the cutting machine

- Data interface to the cutting machine for the transfer of the positions

Palletising line for reels

- Fully automated reel transport with checkweigher

- Palletising system with inside clamping gripper or KOCH special gripper

- automated full- and empty-pallet transport

automated stretch wrapping system

Fully Automated Packaging and Palletising System

- Automated reel transport with pre-grouping

- KOCH special clamping jaw gripper with automatic gripper adjustment for different reel diameters

- Assembling and capper of boxes; checkweigher and labeller

- Palletising system with KOCH multifunctional gripper for boxes and jumbo reels

- automated full- and empty-pallet transport

- up to 1.400 reels/h

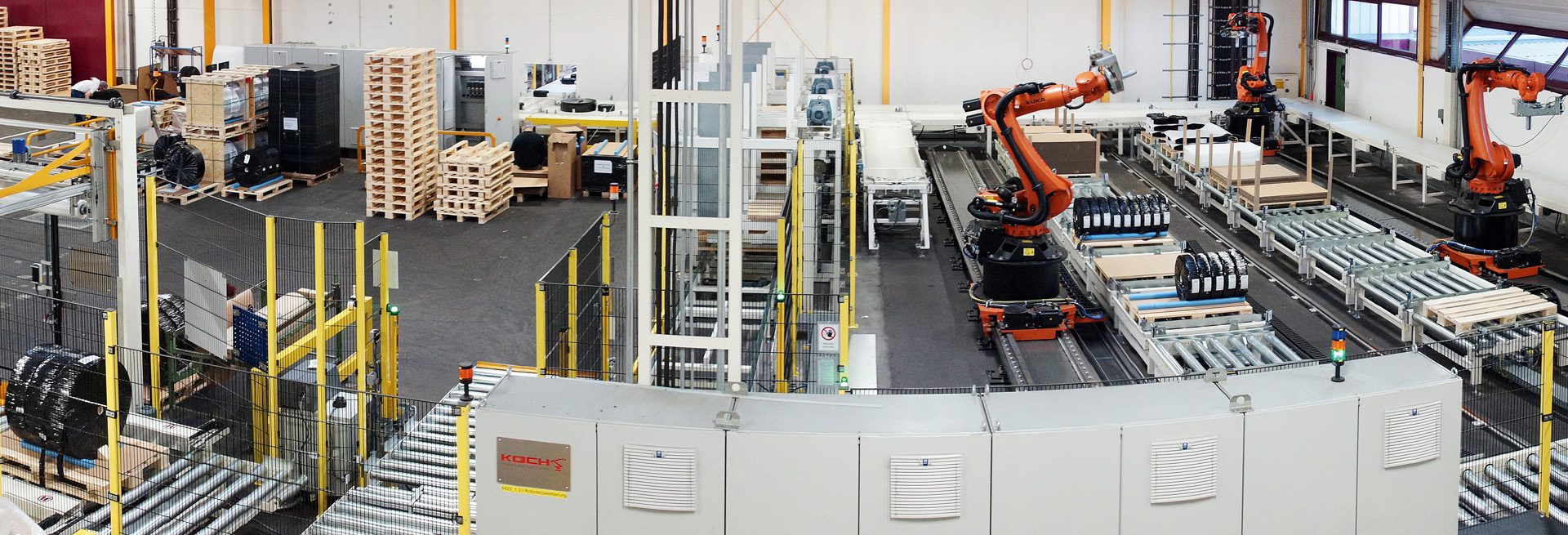

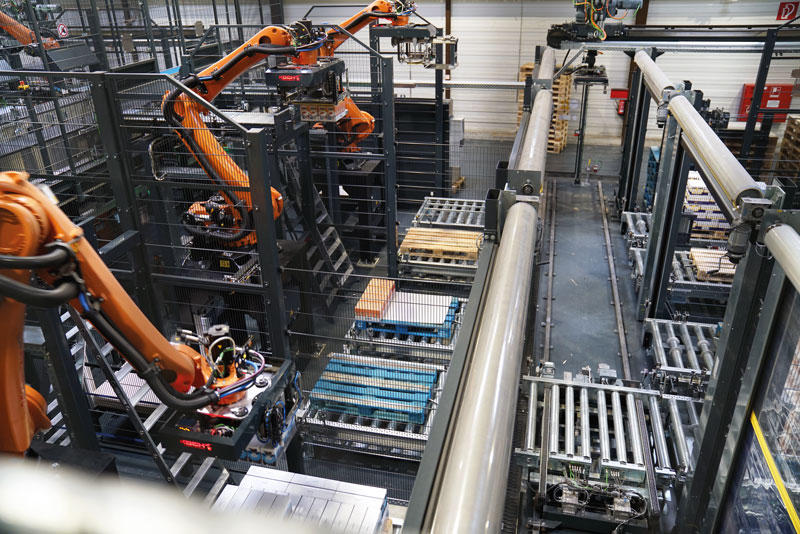

Fully Automated Packaging and Palletising System for reels

- Fully Automated Packaging and Palletising System

- A total of seven robot systems

- Fully automated unloading of three reel splitters, packaging and palletising of reels and load securing

- Automated reel tracking in a chaotic system

- Central palletizing of reels (horizontal or vertical) by three robots on an traversing

- Load securing with a stretch wrapping system and strapping

Palletising line for the food and beverage industries

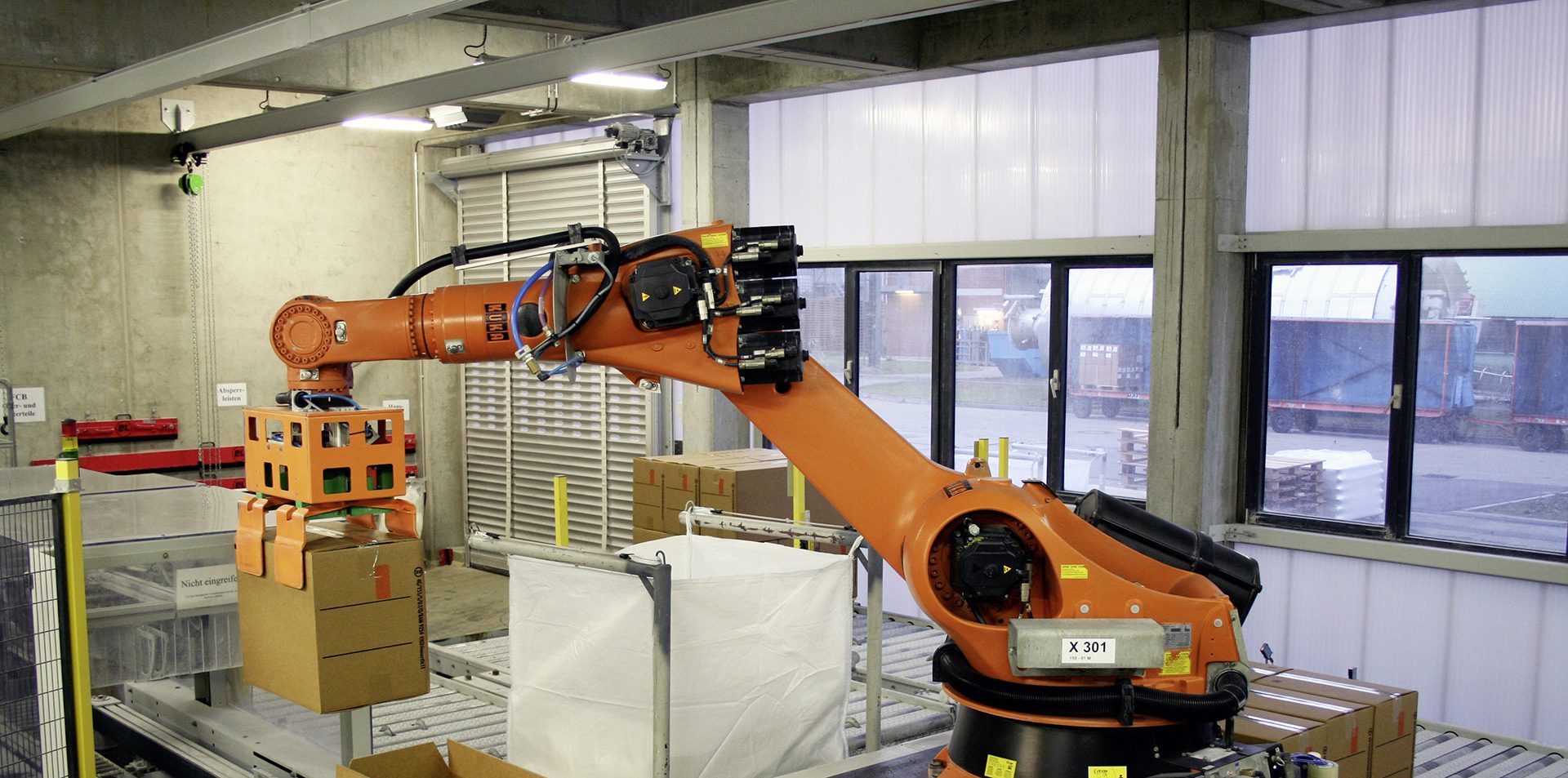

- Depalletising individual bags with a suction gripper

- Layer recognition via 3D vision system

- Layer pregrouping via conveyor system

- Layer gripper for palletising entire pallet layers

- Up to 800 bags/h

Palletising line for silicon carbide

- Handling pallets and intermediate layers

- Multifunction grippers

- Various pallet size

- Includes stretch wrapping

- Up to 400 bags/h

Palletising line for mills and cereal factories

- Palletising two parallel production lines

- Full and empty pallets transported automatically with transfer carrier

- Includes stretch wrapping system

- Interface to upstream system control with marking bags and labelling pallets integrated

- Up to 800 bags/h

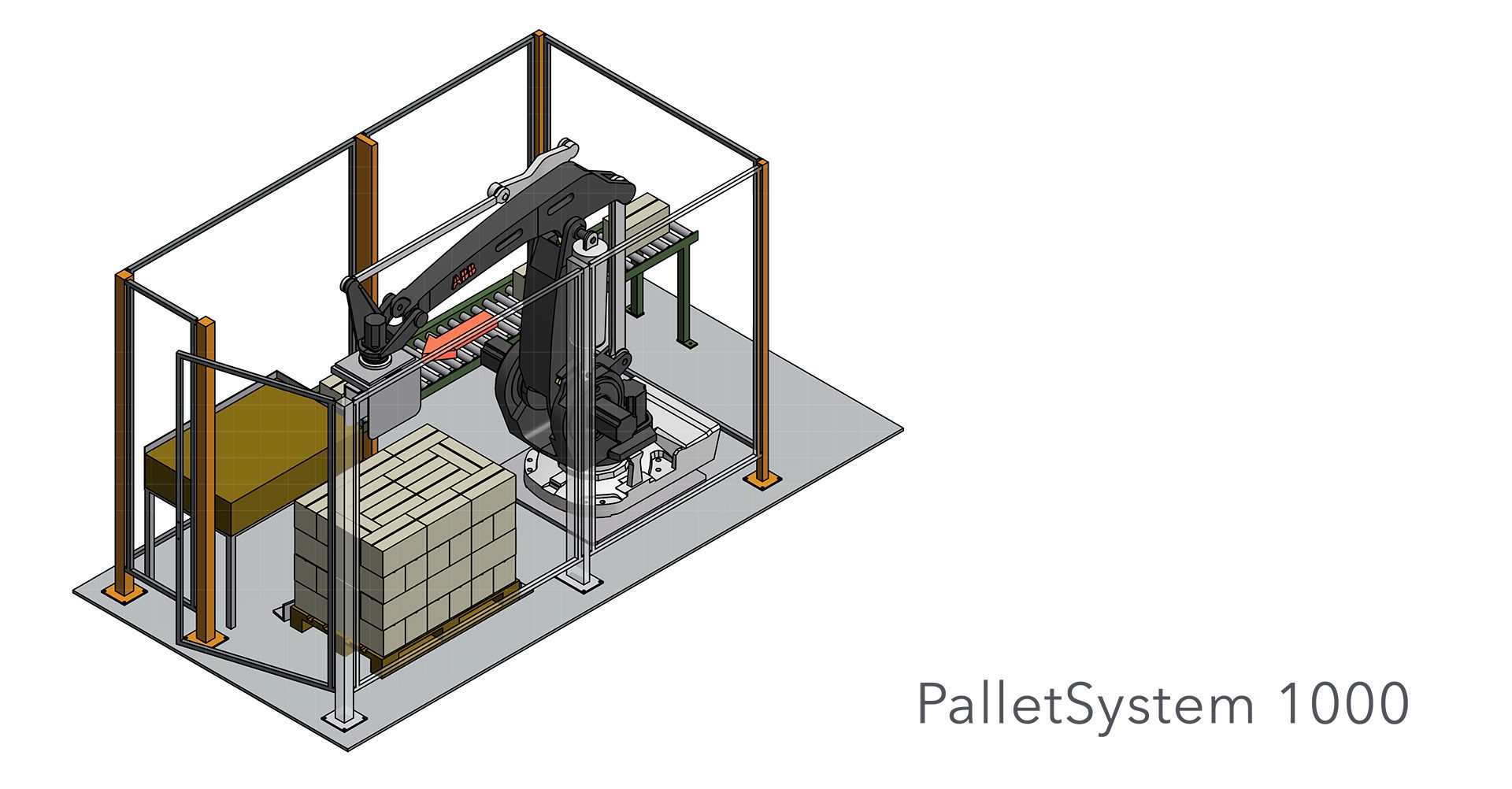

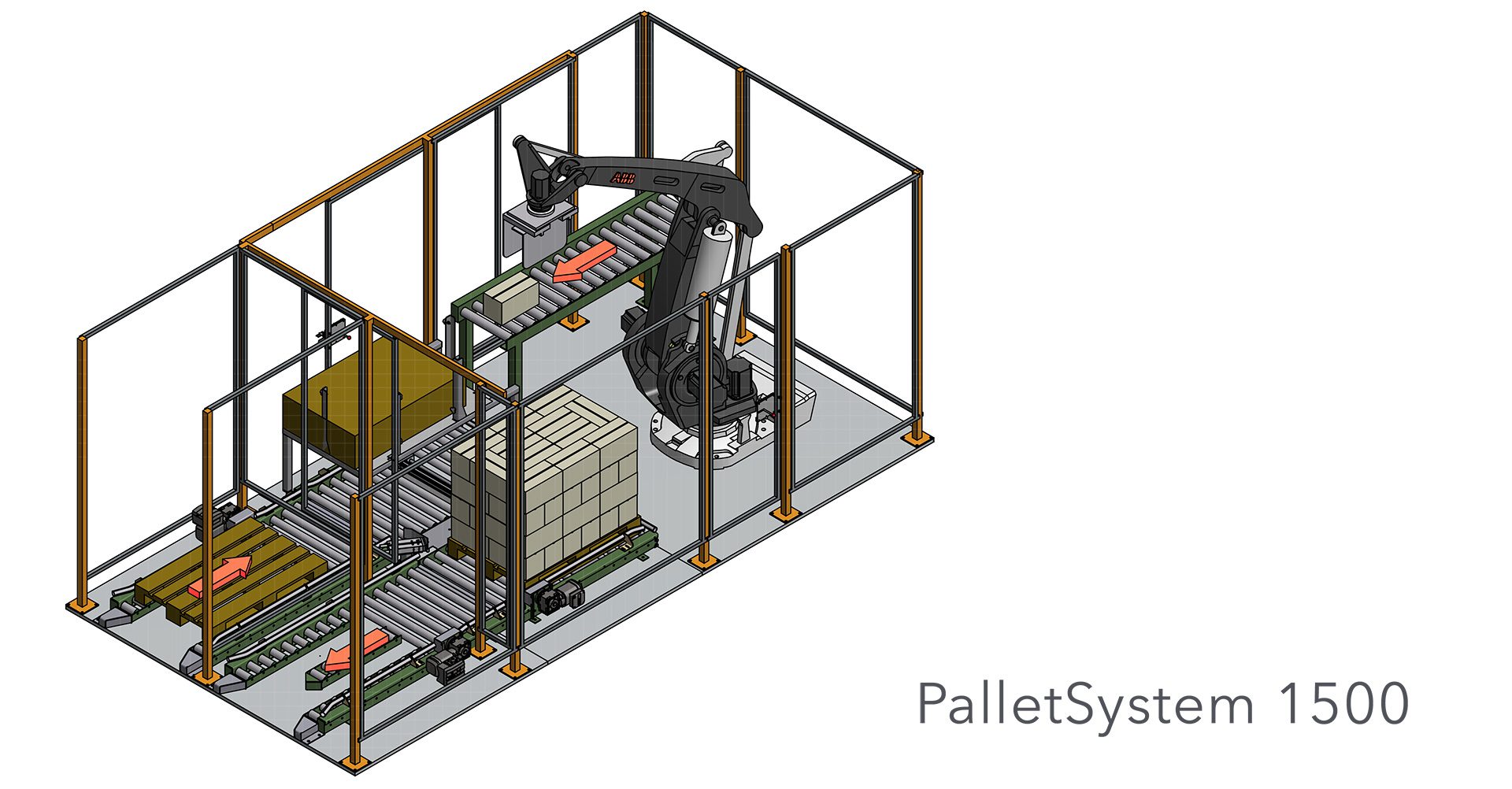

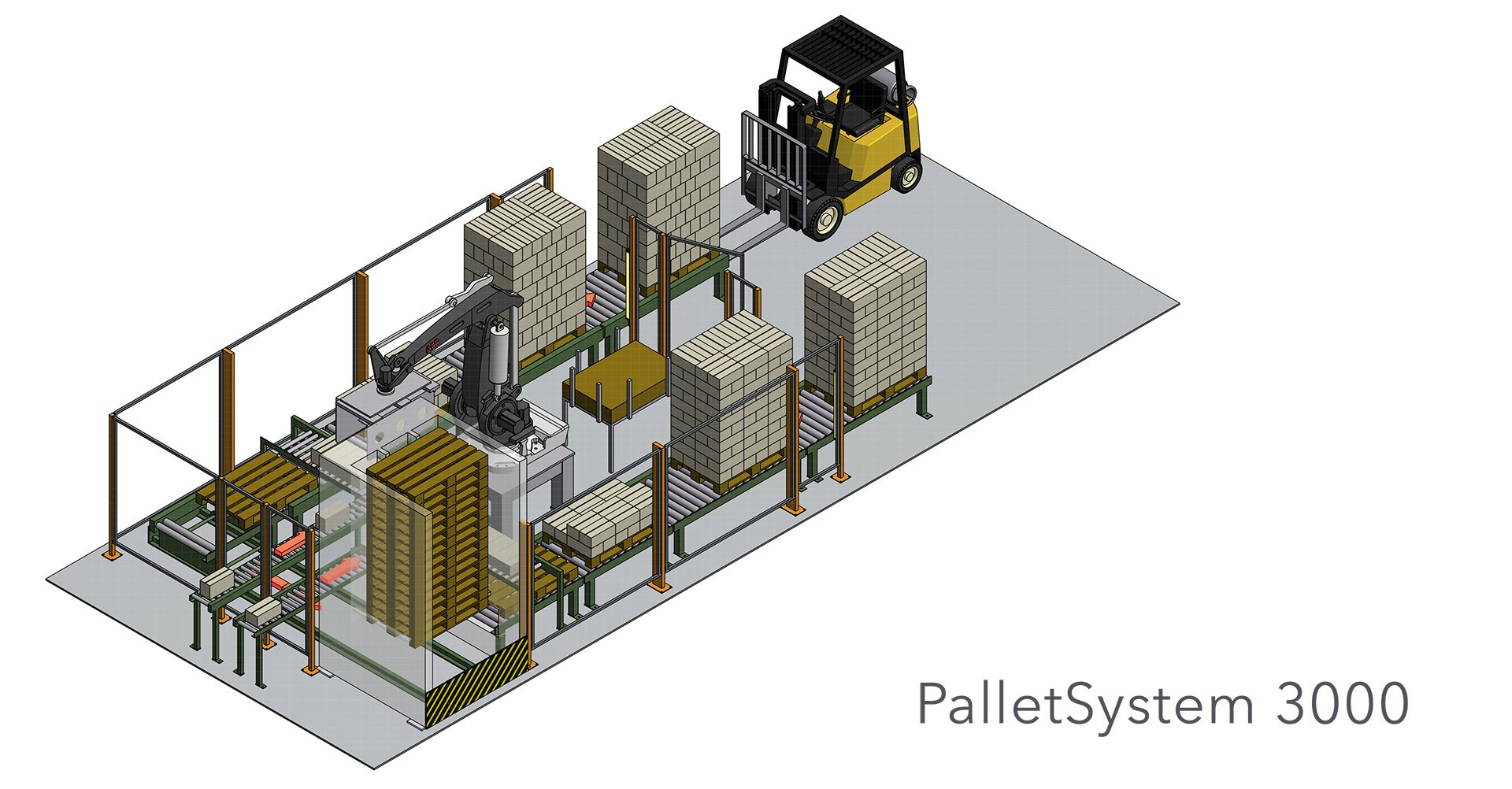

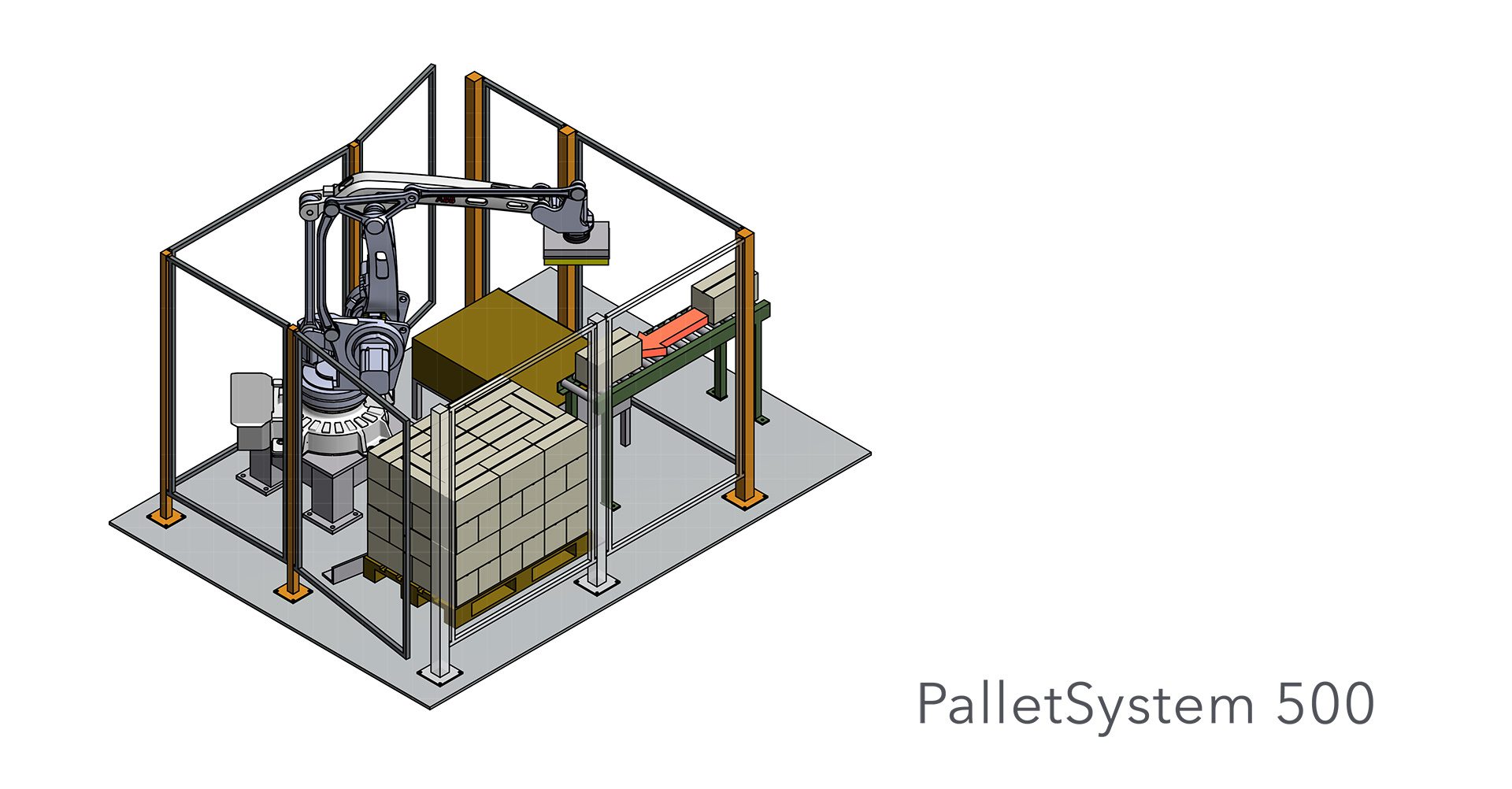

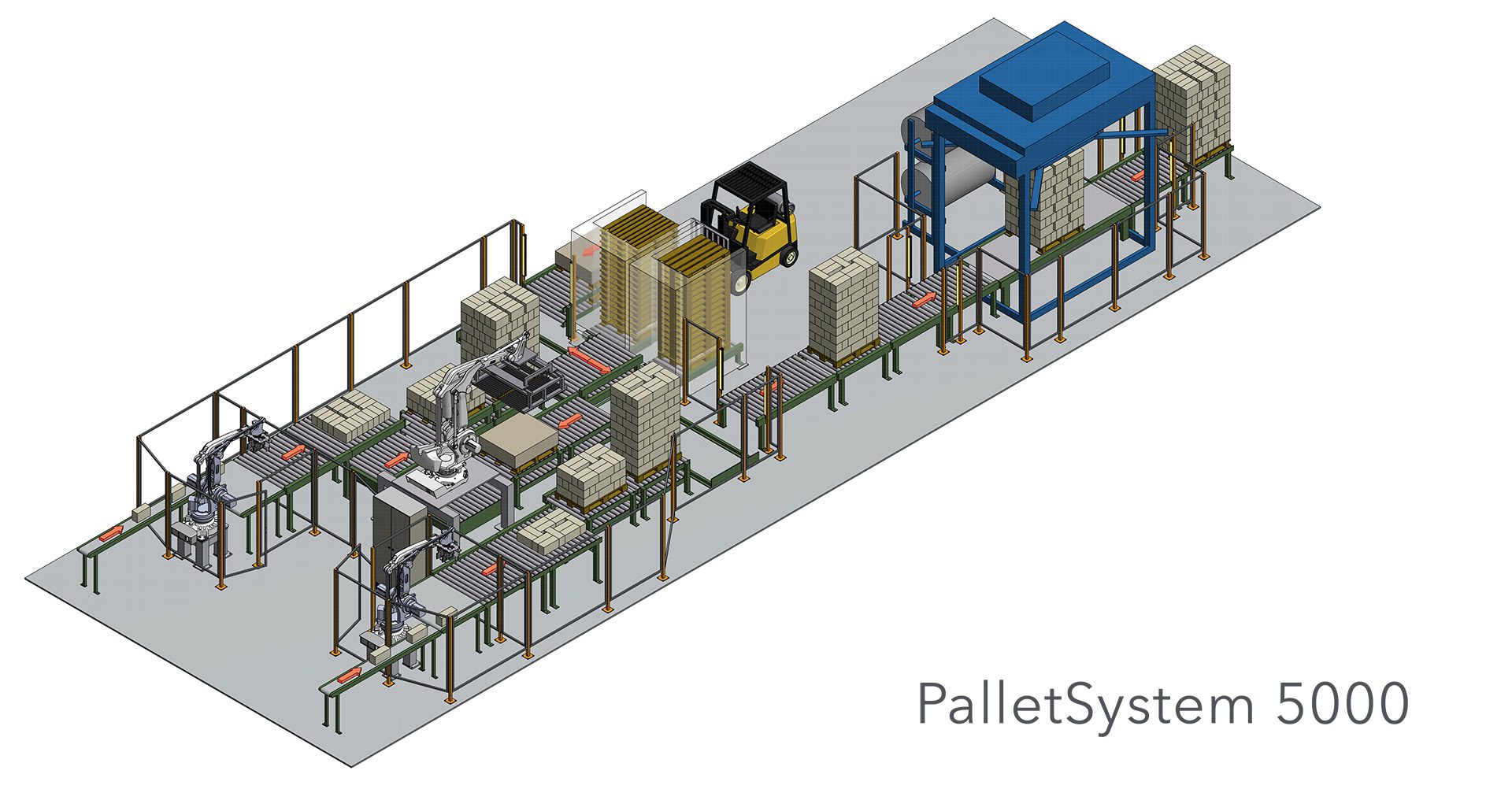

PalletSystems

- Universal solutions: for boxes, trays, crates and other such containers with up to 100kg in weight, 100 – 600 mm in length and 80 – 500 mm in width

- Also suitable for bales, canisters, barrels, drums, hobbocks, pails etc.

- High availabilities of up to 98 %

- Easy to operate: select the products you want via tables on the control panels

- Optional simple setting-up of new packages and stacking patterns with the field-proven KOCH software Easy Pallet

- Minimal loss of value: high life expectancies of 10 – 15 years, trade-in or buy-back possible

- Excellent value for money, low maintenance costs

Palletising line for specialty chemicals

- Setting up boxes, placing bags inside and closing boxes

- Palletising the boxes and bags on pallets or in big bags

- Robot universal grippers

- Full and empty pallets transported automatically

Palletising line for plastic pellets

- Automatic empty pallet magazine and protective sheet gantry for auto

- Matically laying protective sheets

- Bag marking system

- Double-fork grippers

- Includes additional feed unit and stretch wrapping system for different

- Types of pallets

- Up to 900 bags/h

Flexible packaging robot for the food industry

- High packaging speeds thanks to multiple gripping

- Optimum flexibility in adapting to new packaging units and applications which had not been considered before

Palletising line for the flour-milling industry

Includes big-bag filling

- Different types of pallets

- Interface to higher-level process control system with marking bags and

- Labelling pallets integrated

- Full and empty pallets transported automatically

- Includes additional feed unit and stretch wrapping system

- Up to 700 bags/h

Palletising line for building materials

- Order picking of all types of bags

- Depalletising robot on traversing axis with access to 16 pallet locations

- Fork gripper and suction gripper

- Full and empty pallets transported automatically

- Up to 550 bags/h

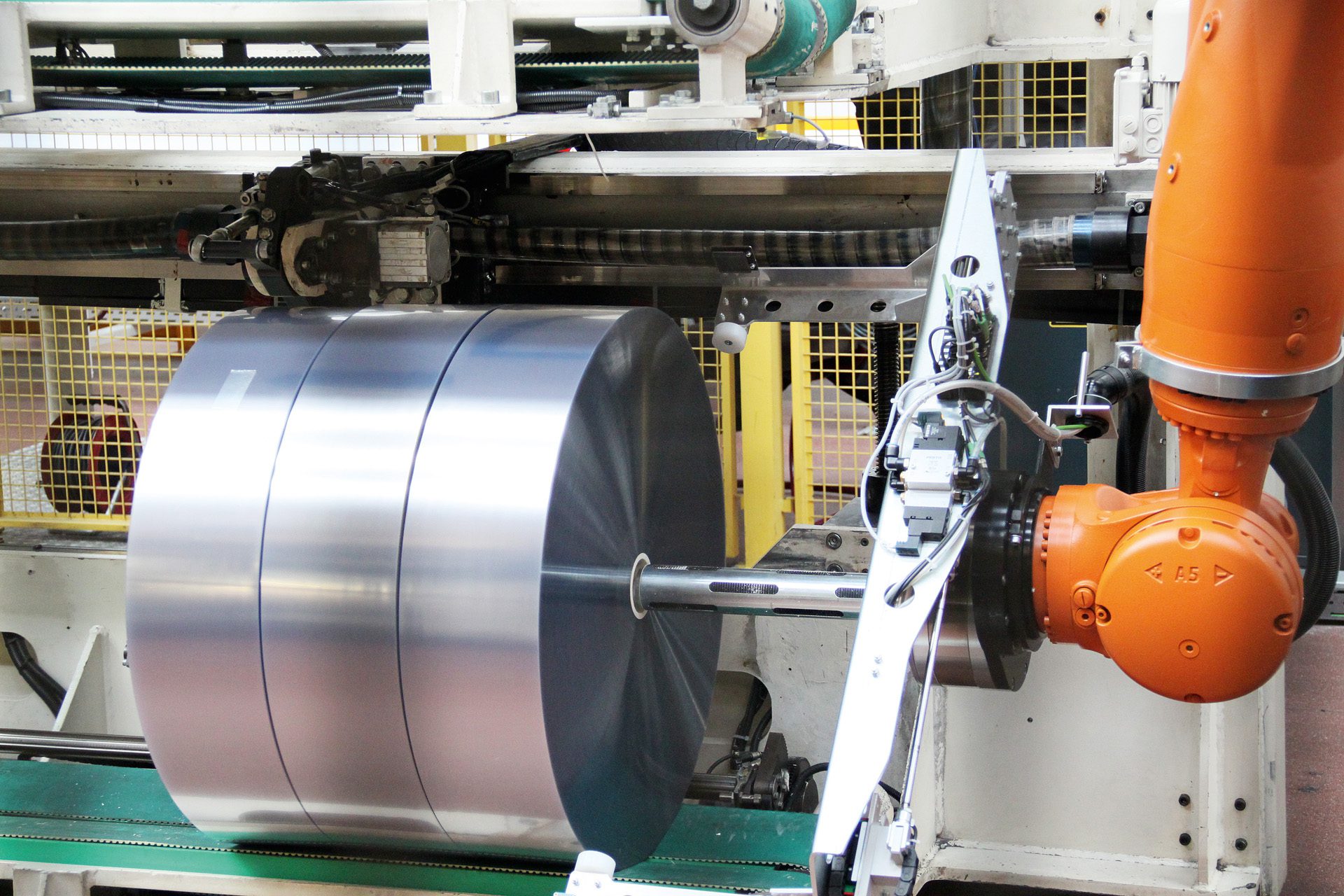

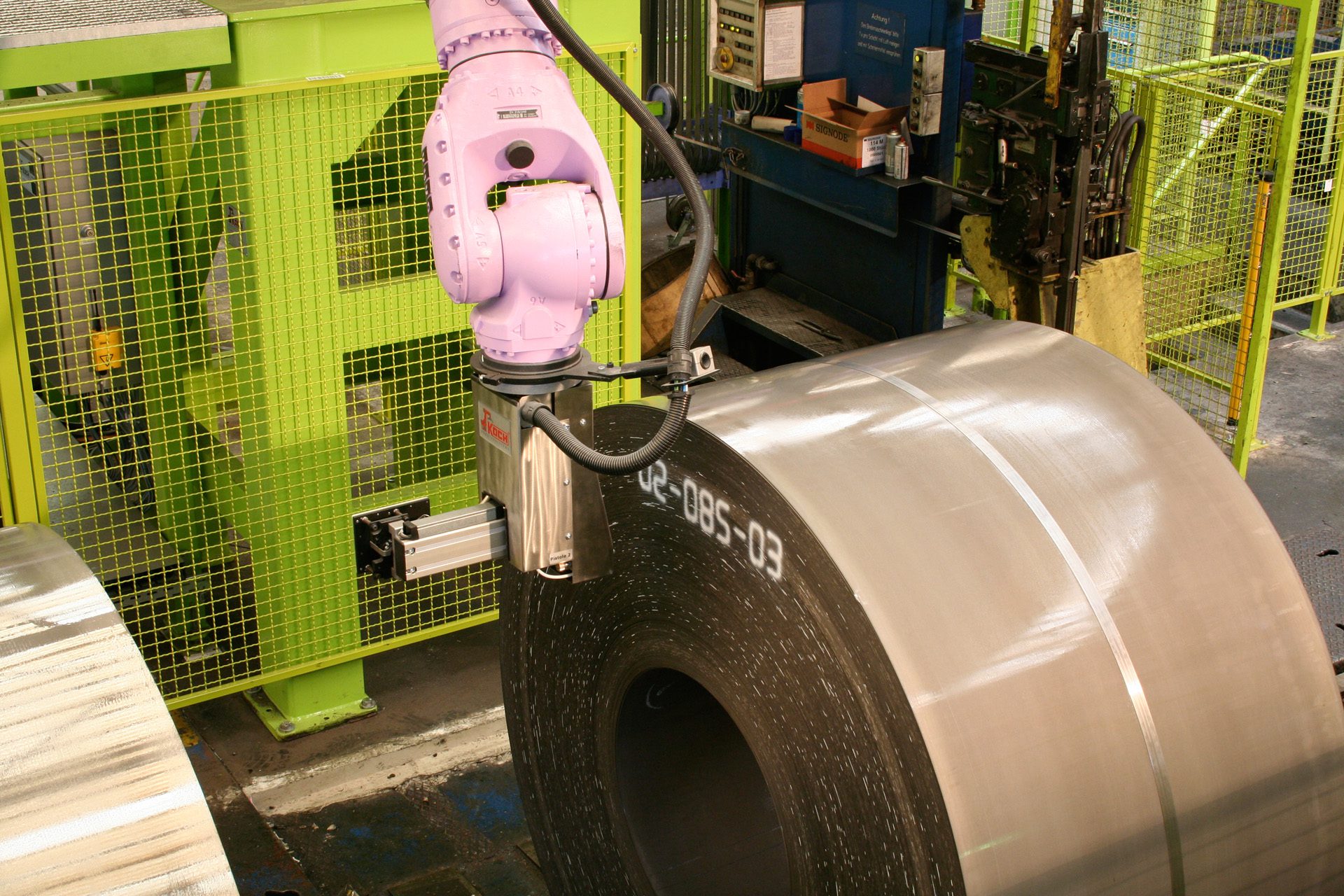

Labelling and marking robot for sheet metal coils

- Labelling: placing bar code labels to within a millimetre on the tying straps of coils

- Marking the circumferential and side surfaces with article numbers by means of inkjet nozzles

- Automatic diameter recognition thanks to measuring sensors

- Linked to the customer’s EDP system

Combined system for flexibly palletising strap rolls

- Palletising both unpacked rolls and rolls packed in boxes at several palletising stations

- Palletising without resetting times thanks to combination gripper with suction and clamping function

- Pallet management matched to production

Fully automatic – from the slitter rewinder to the pallet ready for

- Fully automatic labelling

- Individual packing and picking by type of various film rolls

- Includes securing the load

- KOCH complete system control with product tracking as well as the interfaces required

- Linked to higher-level MIS (material information system)

Palletising line for toiletries

- Compact standard robot palletising cells linked to four packaging lines

- Different types of boxes and trays palletised in all sorts of layer configurations

- KOCH palletising software Easy-Pallet: the system operator can easily set up new stacking patterns or packages any time he wants to and then send the data straight to the robot cells – and he doesn’t even need any programming skills to do it

Filling line for viscous liquid chemical products

Complete filling line for viscous liquid chemical products in cardboard drums with slip-on lid (45kg capacity)

- Palletising robot with combination gripper (for drums, pallets and top boards)

- Features of the filling line:

- automatic empties infeed

- automatic tandem filling

- product weighing

- labelling station

- automatic vertical strapping machine

- full pallets conveyor system

Palletising line for milling industry

- Complete turnkey system

- Packaging/Palletising

- Bags

- Palletising line for the milling industry

- Palletising two parallel production lines

- KOCH Sliding Fork Gripper with automatic gripper adjustment

- protective layer portal; pallet safety and pallet labeller; different pallet formats

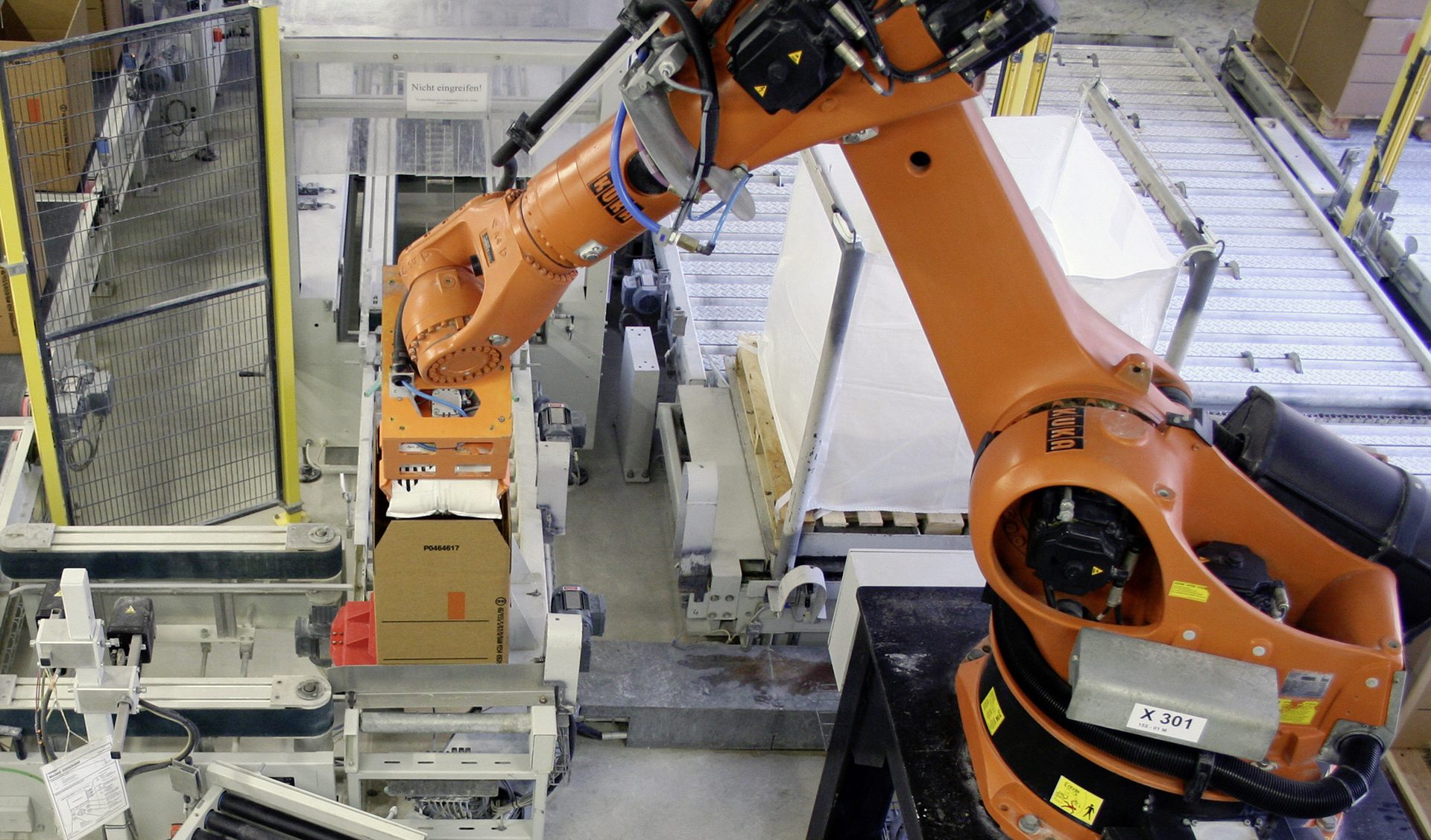

Depalletising of empty jars & palletising of boxes

- Complete turnkey system

- Packaging/Palletising

- Jars and Boxes

- Palletising line for the food industry

- Palletising three parallel production lines with different boxes

- KOCH Clamping Jaw Gripper with under-grip function; protective layer and intermediate layer portal

Palletising system of three production lines for buckets

- Complete turnkey system

- Packaging/Palletising

- Buckets

- Palletising line for dry mortar

- Flexible palletising of buckets with automatic gripper adjustment for parallel and sorted processing of three production lines

Palletising system for boxes and trays

- Integrable individual system / Complete turnkey system

- Packaging/Palletising

- Boxes and trays

- Palletising line for dairy products with different box formats with EasyPallet

- Pre-grouping and automatic gripper adjustment

Fully automatic packaging and palletising line for rolls

- Fully automatic slitter rewinder with capstan handle

- Fully automatic unloading by the robot

- Flexible in the tube diameter – adjustable fully automatically

- Roll transport (eye to wall) with NOK rejection

- Robot palletising with KOCH special gripper for product, pallet and intermediate layer

- Significantly greater output on the slitter rewinder through KOCH robot systems

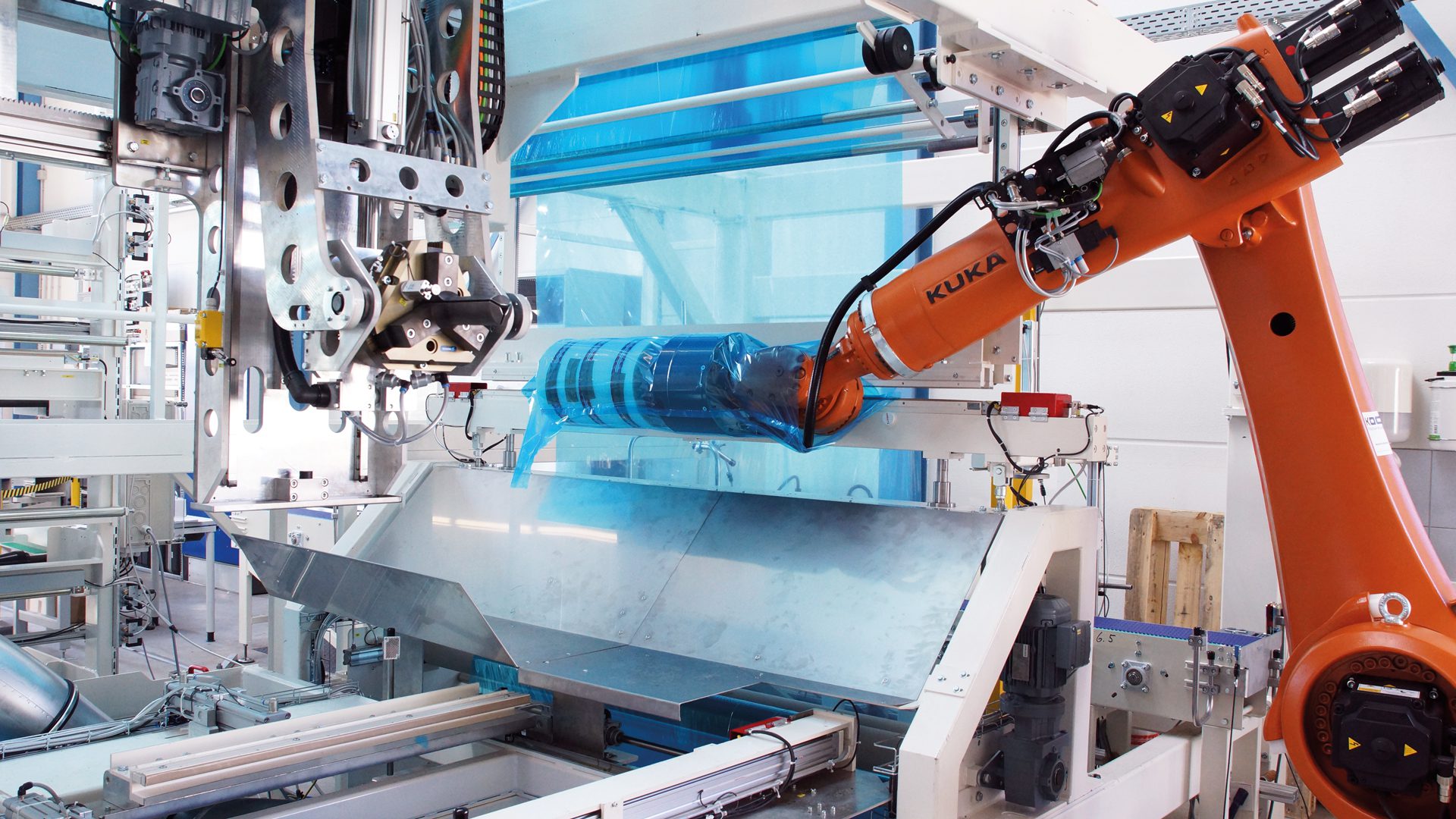

Fully automatic packaging and palletising line for rolls

- KOCH – Robot Flex Packer – RFP 100/150

- Packaging machine for rolls with cutting widths of 50 mm to 600 mm

- Robot removes individual rolls from the feeder conveyor and takes them through a film curtain

- The open sides are then sealed one after the other

- Fully automatic roll transport (eye to wall)

- Fully automatic roll packaging

- Fully automatic empty pallet transport with traverser

- Fully automatic roll palletising (eye to wall or eye to sky)

Palletising system for boxes and trays

- Centralised palletising

- Integrable individual systems

- Universal gripper system for boxes and trays in different sizes

- KOCH-EasyPallet

- Flexible connection to production machines

- Access to different pallet types